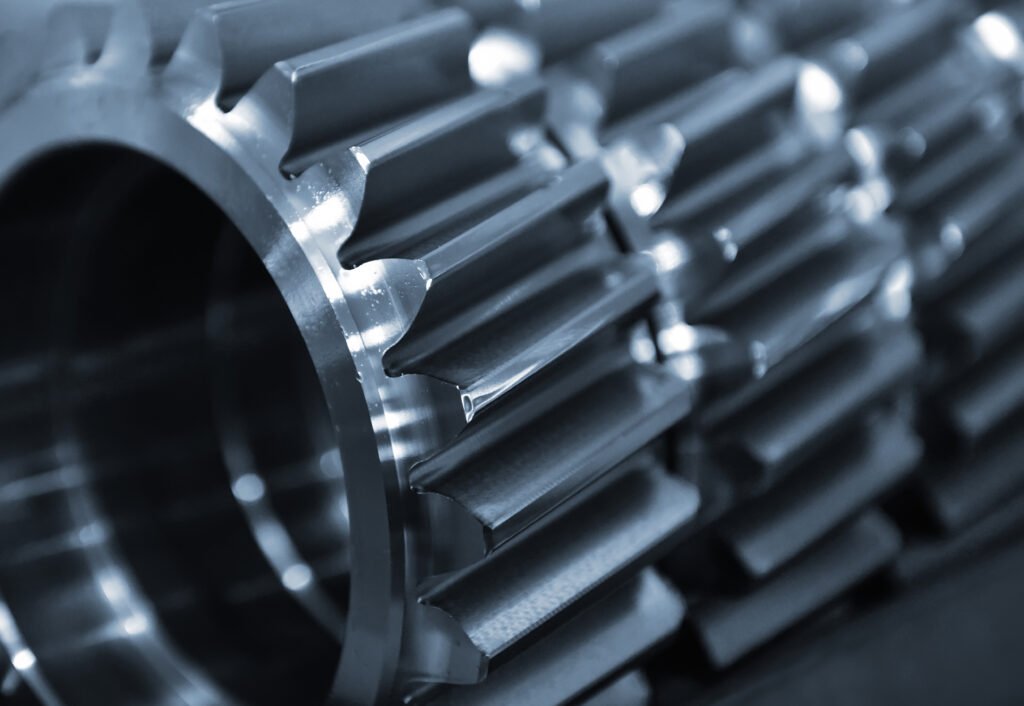

Experts in Engineering Products & Components

Stahlhochtech is a premier manufacturer specializing in engineering products and components, with a core focus on machining and manufacturing products.

Our values

Stahlhochtech utilizes advanced German engineering to deliver high-quality casting, machining, and coating products that meet European standards. We focus on innovative, reliable solutions for water pipelines, valves, and industrial sectors, emphasizing excellence, sustainability, and customer satisfaction.

Expertise

Combining innovation with extensive experience, we ensure top-tier quality and service throughout each project’s lifecycle, adapting to current and future demands.

Sustainability

We prioritize environmental responsibility and build long-lasting, respectful relationships through resource- efficient processes and sustainable practices.

Respect

Reliability and mutual respect are core values at Stahlhochtech, guiding our professional behavior and fostering trust and diversity.

Passion

Our international teams are driven by commitment and enthusiasm, embracing challenges and celebrating successes with our customers.

Collaboration

Transparent communication and strong partnerships with customers, suppliers, and service providers are key to our collaborative approach.

Our Vision

Every aspect of our process aligns with our vision, ensuring error-free manufacturing and competitive rates.

Customer Focus

We prioritize customer satisfaction and adhere to DIN, ISO, and EN 1563 standards for our products.

Industry leadership

We use sophisticated technology to be a reliable supplier for critical industries, including pipelines and valves.

Whole-system approch

Integrating energy and environmental solutions, we adapt our product range for broad industrial applications, supporting customers throughout the plant lifecycle.

Sustainability

We adopt sustainable manufacturing practices to minimize environmental impact and support long-term ecological balance.

Stahlhochtech

Stahlhochtech is a premier manufacturer specializing in engineering products and components, with a core focus on manufacturing, machining and casting. Leveraging deep-rooted expertise we are dedicated to delivering precision-engineered solutions and products for industries such as water pipelines, valve manufacturing, Defence and much more.

Our commitment to excellence is reflected in our adherence to stringent European standards, including DIN , and EN Standards, ensuring that every product

we manufacture meets the highest benchmarks of quality and reliability. At Stahlhochtech, we pride ourselves on our ability to combine cutting-edge technology with advanced manufacturing techniques, positioning us as a trusted partner for industries worldwide.

Flanges.

At Stahlhochtech, we recognize the critical role that flanges play in the water pipeline and valve industry. Upholding the highest standards in manufacturing, we ensure that our flanges are engineered to withstand high-pressure applications, provide precise alignment, and minimize the risk of leaks, even in hazardous environments.

Our product range includes flanges manufactured from a variety of materials, such as carbon steel, cast iron, nickel alloy, stainless steel, bronze, brass, and aluminum. We adhere to stringent material specifications, including DIN EN 10025 and DIN EN 10222, ensuring that our products meet the rigorous demands of industrial applications. In compliance with DIN, EN, and ISO standards, our manufacturing process produces a wide array of flange types, including Weld Neck Flanges, Slip-On Flanges, Blind Flanges, Socket Weld Flanges, Threaded Flanges, Lap Joint Flanges, and Raised Face Flanges.

At Stahlhochtech, our commitment to quality ensures that our flanges deliver reliability, safety, and performance across all applications.

Retainer Ring (Butterfly Valve)

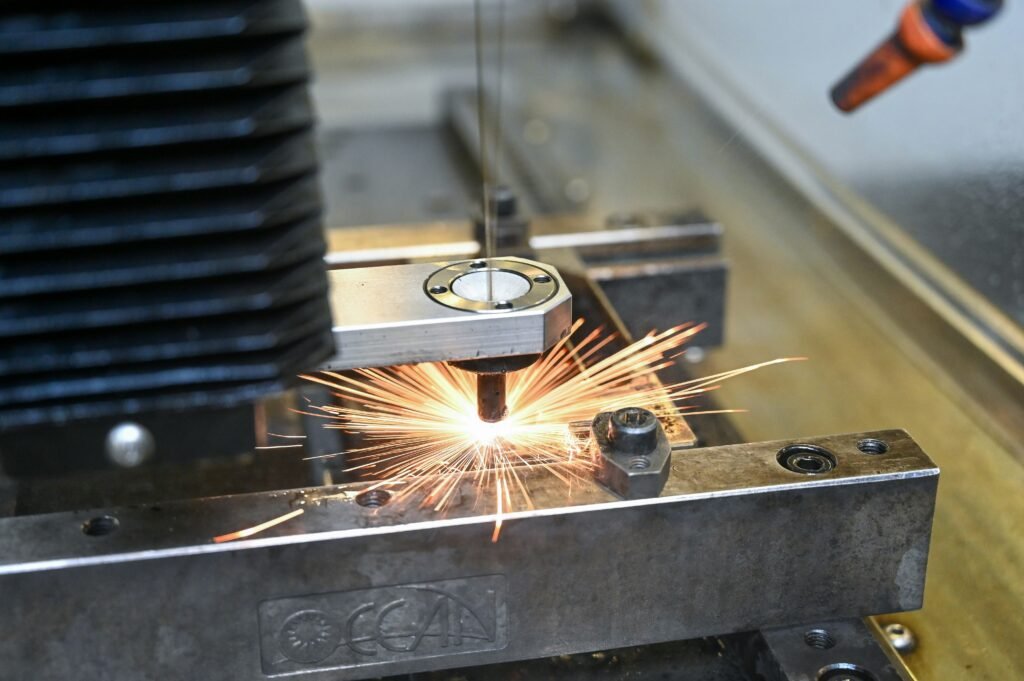

Retainer Rings: Precision, Efficiency, and Reliability by Stahlhochtech

At Stahlhochtech, we understand that retainer rings are critical components in the valve and pipeline industries. They ensure safe, efficient, and low- maintenance operations, ultimately contributing to cost efficiency. Manufacturing a retainer ring is a precise craft, and at Stahlhochtech, we are committed to mastering it. With our expertise in machining and manufacturing, we are dedicated to providing the best retainer rings on the market.

Key Features of Stahlhochtech Retainer Rings.

Component Security

Stahlhochtech retainer rings are engineered to stringent tolerance standards as per DIN ISO 286 and ISO 2768. These precise tolerances prevent displacement during both dynamic and static operations, ensuring secure and reliable performance.

Ease of Maintenance

Our products are designed to minimize maintenance and downtime. We select the highest quality materials, including cast iron and advanced alloys, adhering to standards such as DIN EN ISO 6506-1 , DIN EN ISO 527-1, and DIN EN ISO 6508-1. This commitment to quality ensures long-lasting durability and reduced maintenance needs.

Water Leakage Prevention

The effectiveness of a valve is heavily dependent on its ability to prevent water leakage. At Stahlhochtech, our retainer rings are meticulously crafted to address this issue. The primary cause of leakage is wear and tear, which we combat by enameling our products according to WN 111 056. Additionally, our wear resistance is rigorously tested in compliance with DIN EN ISO 7784-1 standards.

Superior Surface Finish

Stahlhochtech retainer rings and engineering components are expertly coated with corrosion-resistant and abrasion- resistant materials. We maintain surface roughness according to DIN EN ISO 4287 and other European standards, ensuring a flawless finish that enhances both performance and longevity.

Other Engineered products.

At Stahlhochtech, we extend our expertise beyond traditional boundaries, specializing in the manufacturing and machining of high-quality products. Our focus is particularly on serving the valve and water pipeline industries, where we excel in delivering precision-engineered solutions.

Design and Features:

Circular shape

Matches the valve body's internal diameter.

Grooved or notched

Corresponds to the valve disc's shape, ensuring a secure fit.

Material

Typically made from stainless steel, carbon steel, or other corrosion-resistant materials.

Thickness and diameter

Varies depending on valve size and application.

Benefits:

1. Ensures valve integrity: Prevents disc misalignment, stem damage, and valve failure.

2. Smooth operation: Maintains proper stem and disc alignment for efficient valve operation.

3. Longer valve life: Reduces wear and tear on valve components, extending its lifespan.